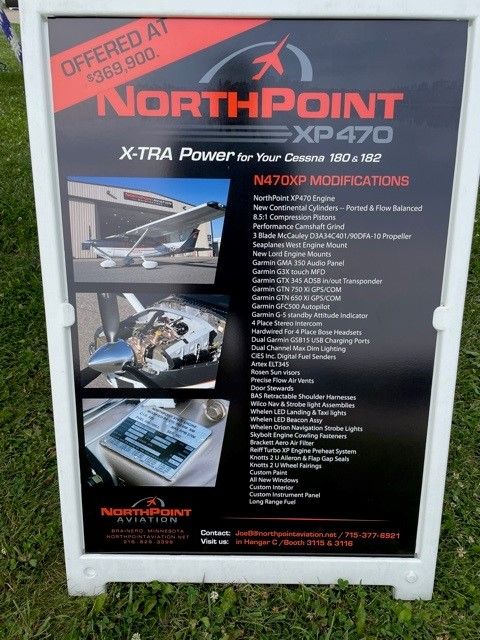

Engine Conversion Specs & Information

Free HP vs. Installed HP

Free HP 0-470: 230

Free HP NorthPoint XP470: 265 HP standard 7.5:1 compression pistons (275 HP w/8.5:1 compression pistons)

Installed HP 0-470: 195 to 200

Installed HP NorthPoint XP470: 235

NorthPoint XP470 Recommended TBO: 1700 Hrs with an oil screen; 2000 Hrs with an oil filter installed since major overhaul

Free HP NorthPoint XP470: 265 HP standard 7.5:1 compression pistons (275 HP w/8.5:1 compression pistons)

Installed HP 0-470: 195 to 200

Installed HP NorthPoint XP470: 235

NorthPoint XP470 Recommended TBO: 1700 Hrs with an oil screen; 2000 Hrs with an oil filter installed since major overhaul

Engine / Aircraft Performance Comparison

| MP | RPM | Altitude | OATC | Stock 0-470 | NorthPoint XP470 | |

| 24 | 2450 | 4000 | 22 | N/A | 158ktas / 182mpht | |

| 23.5 | 2600 | 4000 | 24 | N/A | 164ktas / 189mpht | |

| 23 | 2400 | 4000 | 22 | 142ktas / 163mpht | 154ktas / 178mpht | |

| 22 | 2400 | 6000 | 19 | 142ktas / 163mpht | 155ktas / 178mpht | |

| 22 | 2500 | 6000 | 19 | 145ktas / 167mpht | 158ktas / 182mpht | |

| 21 | 2300 | 8000 | 15 | 138ktas / 159mpht | 152ktas / 175mpht |

Continental 0-470 Engine Modifications

Continental 0-470 engines may be modified only at NorthPoint Aviation or at a facility we have authorized.

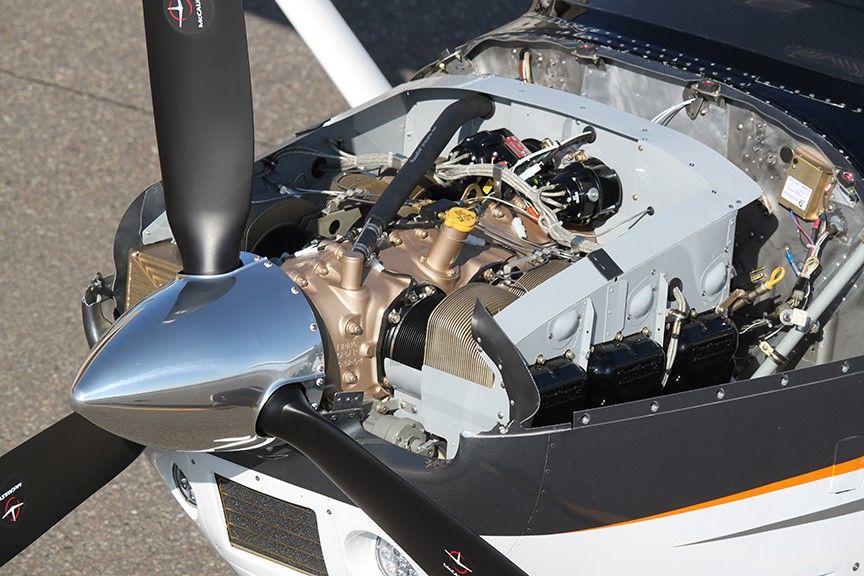

To convert a stock Continental 0-470 engine to the NorthPoint XP470 requires several internal changes, but the first and most obvious is to exchange the 0-470 cylinders for 0-520 cylinders which increase the engine displacement by 50 cubic inches. NorthPoint XP470 Engines are equipped with 4-counterweighted crankshafts. (Most O-470-R and S models will require a crankshaft change.) The crankshaft counterweights are reconfigured and the case is modified. The cylinders are equipped with 7.5 to 1 compression pistons which are precision balanced to within .5 grams. The carburetor is also modified. The original external accessories are serviced as needed or upgraded as desired and installed.

To convert a stock Continental 0-470 engine to the NorthPoint XP470 requires several internal changes, but the first and most obvious is to exchange the 0-470 cylinders for 0-520 cylinders which increase the engine displacement by 50 cubic inches. NorthPoint XP470 Engines are equipped with 4-counterweighted crankshafts. (Most O-470-R and S models will require a crankshaft change.) The crankshaft counterweights are reconfigured and the case is modified. The cylinders are equipped with 7.5 to 1 compression pistons which are precision balanced to within .5 grams. The carburetor is also modified. The original external accessories are serviced as needed or upgraded as desired and installed.

Piston Comparison

| Stock 0 -470 | 7 to 1 compression pistons | |

| NorthPoint XP470 | 7.5 to 1 compression pistons | |

| Stock I0-520-D or F | 8.5 to 1 compression pistons |

Continental 520 Engine Conversions

Continental 520 engines may be converted by one of our authorized facilities, or at the facility of your choice, subject to authorization and purchase of STC paperwork. The TSIO-520-C, H, R, M, P, Tor IO-520- D or F engine blocks may be converted. Conversion of eligible TSIO-520 models to the NorthPoint XP470 Engine requires mostly external modifications. Most noticeably is the removal of the turbocharger and fuel injection system and installation of a modified carburetor. Cylinders are equipped with 7.5 to 1 compression pistons, precision balanced to within .5 grams. The oil pan is exchanged for the original oil pan installed on the Cessna 180 or 182.

Carburetor Modification

Modification of an eligible MA4-5 carburetor is required for use with the 0-470-50 engine. Overhaul of the carburetor at the time of modification is recommended unless it has been recently overhauled, or is in excellent condition.

Eligible MA4-5 Part Numbers are: 10-3965-12-1, 10-4893-1, 10-5192 or 10-5284. With authorization from NorthPoint, the carburetor modification (an overhaul as well) may be accomplished by AvStar Fuel Systems in Florida, Professional Aircraft Accessories in Ohio, or LyCon Rebuilding in California.

Whether converting a Continental 470 or 520 to the NorthPoint XP470 Engine, the end product is essentially the same – a carbureted Continental 0-520 which rated 265-275 HP.

A precision balanced engine offers several advantages, including significantly improved performance, smoother operation, less maintenance, and a longer TBO. A smooth running engine also reduces pilot fatigue and increases passenger comfort.

Engine prices are not addressed here as we do not control pricing or warranty of the shops we have authorized to perform the engine conversion. There are many parts and accessory options available including a choice of cylinders that affect pricing, so please contact us or one of our authorized engine builders to discuss your specific needs.

Eligible MA4-5 Part Numbers are: 10-3965-12-1, 10-4893-1, 10-5192 or 10-5284. With authorization from NorthPoint, the carburetor modification (an overhaul as well) may be accomplished by AvStar Fuel Systems in Florida, Professional Aircraft Accessories in Ohio, or LyCon Rebuilding in California.

Whether converting a Continental 470 or 520 to the NorthPoint XP470 Engine, the end product is essentially the same – a carbureted Continental 0-520 which rated 265-275 HP.

A precision balanced engine offers several advantages, including significantly improved performance, smoother operation, less maintenance, and a longer TBO. A smooth running engine also reduces pilot fatigue and increases passenger comfort.

Engine prices are not addressed here as we do not control pricing or warranty of the shops we have authorized to perform the engine conversion. There are many parts and accessory options available including a choice of cylinders that affect pricing, so please contact us or one of our authorized engine builders to discuss your specific needs.

Approximate NorthPoint XP470 Engine Power Settings

The normal lean mixture at approximately 2500 feet:

| Full Manifold Pressure | 27 to 28″ | + 2700 RPM= | 100% power | |

| Full Manifold Pressure | 24″ | + 2400 RPM= | 75% power | |

| Full Manifold Pressure | 23″ | + 2300 RPM= | 65% power | |

| Full Manifold Pressure | 22″ | + 2200 RPM= | 56% power |

Approximate Fuel Consumption

Approved for 100 octane fuel.

- 11.5 gal per hour at 2150 squared

- 16 to 17 gal per hour at 2500 to 2600

- 0-470 engine 1O miles per gallon

- -50 engine 11 miles per gallon

Propellers for the NorthPoint XP470 Engine

Best all-around performance of the NorthPoint XP470 engine is attained with the installation of a 3-blade propeller. Hartzell, McCauley, and MT offer excellent products with similar performance figures, but they have different flight characteristics. It is best to match the propeller with the kind of flying you intend to do.

The McCauley offers a little more thrust and acts somewhat like a speed brake when setting up for landing. (Very helpful in and out of short strips with heavy loads.) The Hartzell is a little faster, and also a quieter prop if you are operating in noise sensitive areas. The MT is a lighter weight option.

Please Note:

NorthPoint XP470 engine installation includes installation of approved McCauley propellers.

NorthPoint XP470 installation of approved Hartzell propellers is separate and is included with the purchase of a Hartzell propeller from NorthPoint Aviation.

An MT Prop option and STC for installation with the NorthPoint XP470 engine is available through Flight Resources.

The McCauley offers a little more thrust and acts somewhat like a speed brake when setting up for landing. (Very helpful in and out of short strips with heavy loads.) The Hartzell is a little faster, and also a quieter prop if you are operating in noise sensitive areas. The MT is a lighter weight option.

Please Note:

NorthPoint XP470 engine installation includes installation of approved McCauley propellers.

NorthPoint XP470 installation of approved Hartzell propellers is separate and is included with the purchase of a Hartzell propeller from NorthPoint Aviation.

An MT Prop option and STC for installation with the NorthPoint XP470 engine is available through Flight Resources.

NorthPoint XP470 STC’s for Cessna 182

- Modification of O-470K, L, M, R, Sand U to NorthPoint XP470.

- Modification of TSIO-520-C engine to NorthPoint XP470.

- Installation of-NorthPoint XP470 engine in all Cessna 182, and 182A through R

- Installation of the following propellers:

- McCauley D2A34C58/90AT-8 (2 blades)

- McCauley 2A34C66/90AT-8 (2 blade)

- McCauley D2A37C230/90REB-8 (2 blades)

- McCauley D3A32C90/82NC-2 (3 blades)

- McCauley D3A34C401/90DFA-10 (80″ I 3 blade I Cessna 182 H through R)

- McCauley D3A34C401/90DFA-8 (82″ I 3 blade I Cessna 182 through G)

- Hartzell PHC-G3YF-1RF/F8429-6 (3-blade Voyager 80″ Cessna 182 H through R)

- Hartzell PHC-C/G3YF-1RF/8068 (82″ I 3-blade I C/G = c or G Hub)

- Hartzell PHC-C/G3YF-1 RF/8068+2 (84″ I 3-blade I C/G = C or G Hub Seaplane Only or Landplane with approved nose fork and larger

NorthPoint -50 STC’s for Cessna 180

- Modification of O-470K, L, M, R, Sand U toNorthPoint XP470.

- Modification of TSIO-520-C engine to NorthPoint XP470.

- Installation of -50 engine in all Cessna 180 and 180A through 180K

- Installation of the following propellers:

- McCauley D3A34C401/90DFA-2 to -10 80″ to 88″ 3-blade

- Hartzell PHC-C3YF-1RF/F8429 (3-blade Voyager 86″)

- Hartzell PHC-C/G3YF-1 RF/8068 (82″) or 8086+2 (84″) 3-blade (C/G = C or G Hub)